From Lab to Clothing: Powering the Future with Solar Textiles

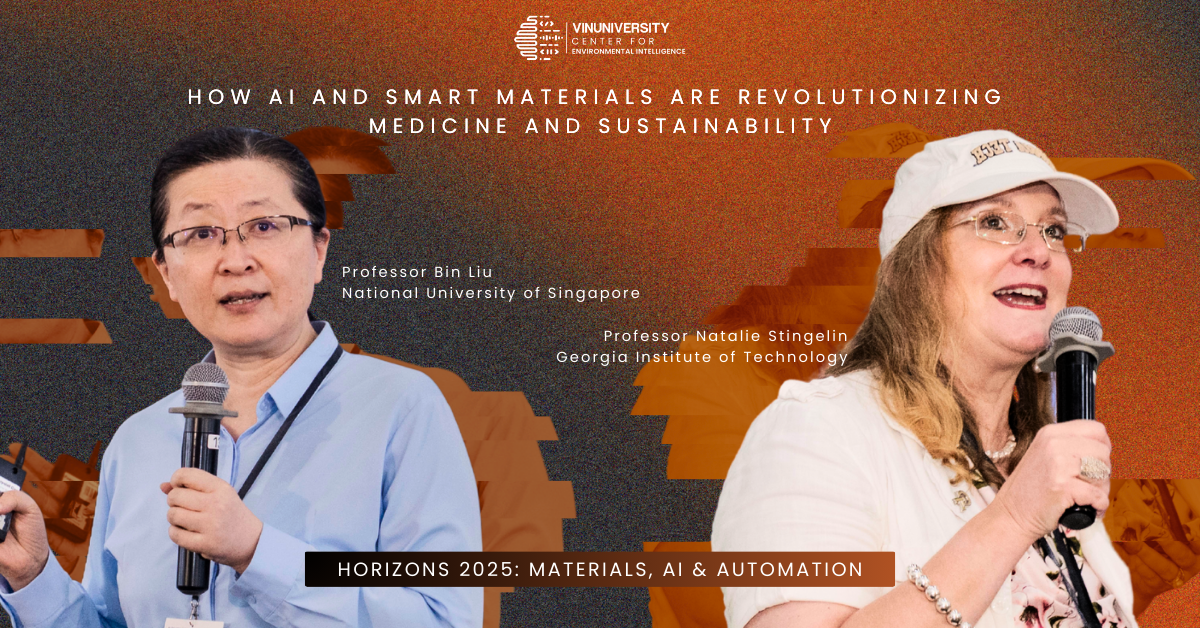

The Horizons 2025: Materials, AI & Automation conference has concluded with over 70 presentations showcasing research achievements and breakthroughs from scientists representing more than 20 countries. This remarkable gathering illuminated the future of materials science, particularly through two particularly plenary talks. Professor Bin Liu’s pioneering work on “Accelerating Biomedical Research through Materials Innovation” and Professor Natalie Stingelin’s revolutionary research on environmentally-conscious smart plastics represent a fundamental shift in how we approach both human health and planetary sustainability. These aren’t just incremental improvements, they’re paradigm changes that promise to transform entire industries.

Professor Bin Liu‘s presentation on AIEgens (Aggregation-Induced Emission luminogens) revealed a fascinating paradox in materials science that’s now saving lives. Unlike conventional materials that dim when crowded together, these “shy materials” actually shine brighter when they aggregate, much like introverted students who become animated when they find their tribe.

This unique property has profound implications for cancer treatment. Traditional chemotherapy operates like a carpet bomb, devastating healthy cells alongside cancerous ones. Professor Liu’s AIEgens represent precision warfare at the molecular level. These intelligent materials remain dormant until they encounter the specific conditions found within tumors: low oxygen environments, particular pH levels, or specific cellular markers. Only then do they “switch on,” generating reactive oxygen species that selectively destroy cancer cells while leaving healthy tissue unharmed.

What makes Professor Liu’s work particularly revolutionary is the integration of artificial intelligence (AI) into the materials discovery process. Traditional materials development has been notoriously slow and expensive, often requiring years of trial-and-error experimentation. Imagine trying to find the perfect recipe by randomly combining ingredients without any understanding of how they interact, that’s been the reality of materials science for decades.

AI changes this paradigm entirely. Instead of blindly testing thousands of combinations in the laboratory, researchers can now use machine learning algorithms to predict which materials will exhibit desired properties before they’re even synthesized. The AI learns from each experiment, continuously refining its predictions and accelerating the discovery process from years to months or even weeks.

This computational approach has enabled Professor Liu’s team to develop materials that function as “oxygen batteries”- storing oxygen-releasing molecules when not needed and delivering them precisely when and where required. For cancer patients in low-oxygen tumor environments, this could mean the difference between effective treatment and resistance to therapy.

Professor Liu’s AIEgens extend far beyond cancer applications. The team has developed new fluorescent bioprobes for biosensing and imaging that take advantage of the unique aggregation-induced emission characteristics. These materials can be engineered to respond to specific biological markers, lighting up only when they encounter particular proteins, enzymes, or cellular conditions.

Unlike conventional fluorescent materials that often suffer from quenching effects when concentrated, AIEgens become brighter in crowded biological environments. This makes them ideal for detecting biomolecules at high concentrations or in complex biological systems where traditional fluorescent probes would fail. The materials can illuminate specific cellular structures, track biological processes in real-time, and provide unprecedented clarity in medical imaging applications.

Professor Natalie Stingelin‘s presentation challenged a fundamental assumption about plastics and environmental protection. Rather than viewing plastics as inherently harmful, Professor Stingelin and her research team are reimagining them as potential solutions to climate change and sustainability challenges. This represents a crucial shift from elimination to transformation.

The numbers are sobering: plastics currently contribute 5% of global CO₂ emissions, and this figure could reach 15% by 2050 without intervention. However, the solution isn’t necessarily a plastic-free world, it’s a smart-plastic-powered one.

The most compelling applications lie in building integration. Imagine windows that generate electricity while automatically adjusting light and heat transmission based on weather conditions and occupancy. These aren’t science fiction concepts, they’re emerging realities. Smart plastic films can reduce air conditioning costs by up to 30% while simultaneously producing renewable energy.

These materials function as “waveguides for light,” directing solar energy exactly where it’s needed while filtering out harmful radiation. In agricultural applications, greenhouse films optimize light spectra for plant growth while protecting crops from UV damage, potentially extending growing seasons and improving yields in regions affected by climate change.

What makes Professor Stingelin’s advances possible is a fundamental shift in how we manufacture materials. Traditional plastic production resembles industrial-age mass production: crude, wasteful, and inflexible. The new approach employs precision techniques borrowed from electronics manufacturing: laser writing to create molecular patterns, temperature gradients to control material properties, and even 3D printing at the molecular level.

This precision manufacturing enables the creation of materials with multiple functions integrated into a single structure. A plastic film might simultaneously generate electricity, control light transmission, monitor environmental conditions, and respond adaptively to changing circumstances.

The breakthroughs showcased at Horizons 2025 hold particular significance for Vietnam’s rapidly evolving scientific landscape. As the country positions itself as a regional hub for technology and innovation, the convergence of AI-driven materials science and sustainable solutions aligns perfectly with Vietnam’s national development goals.

For developing nations like Vietnam, these advances offer opportunities to leapfrog traditional industrial development paths. Instead of building energy infrastructure based on fossil fuels, countries can integrate smart materials into new construction, creating buildings that generate renewable energy from day one. Agricultural regions can adopt smart greenhouse technologies that improve food security while adapting to changing climate conditions.

Despite these promising advances, one fundamental challenge remains: how do we ensure these breakthrough technologies reach those who need them most, particularly in developing regions where healthcare access is limited and environmental challenges are most acute? While Professor Liu’s targeted cancer therapies and Professor Stingelin’s sustainable materials offer unprecedented possibilities, the gap between laboratory innovation and global accessibility continues to widen.

The question isn’t just technical, it’s deeply ethical and economic. How do we prevent these transformative technologies from exacerbating global inequalities rather than addressing them? The answer lies in international collaboration, technology transfer initiatives, and sustainable business models that prioritize impact alongside innovation.

The materials revolution is not coming, it’s here. The question is whether we’ll seize this moment to build a world where cutting-edge science serves everyone, or allow these powerful tools to remain confined to laboratories and elite institutions. The choice, like the materials themselves, is in our hands to shape.